Project Sol-37 - All Wheel Drive CRX del Sol

It can't be said when exactly this project was concieved, but it is safe to say that the idea started sometime in the year 2000 with the question "Wouldn't it be fun to go rally in an all wheel drive del Sol?" Between then and mid 2004 there was little progress aside from trying to figgure which donor vehicle would be the best choice to source parts from.

An article in Honda Tuning's June 2003 issue briefly spoke about ProMotion Motorsports' ITR and how they wanted to do an all wheel drive conversion for rally as well. The article also mentioned Honda's factory all wheel drive models that weren't sold in the US. However, the article did not mention anything about when this conversion would happen or if there would be any follow up on the project. I'm not aware of any such follow up article.

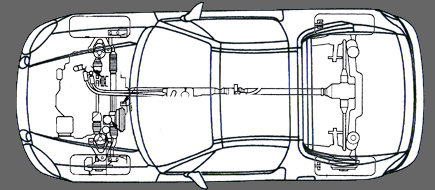

Tward the end of summer in 2004 a little known Honda wagon was located in a salvage yard. It was a 1989 Civic Wagovan RT4WD. It wasn't truely four wheel drive in the sense that the front and rear differentials were phsyically connected with a transfer case, it had a viscous coupling between the front and rear differentials making it all wheel drive and was thought to be the perfect donor vehicle. It was stripped of its rear trailing arms, rear axles, rear differential, front and rear drive shafts, viscous coupling, transmission, shifter and shift cables. Every part of the drivetrain sans engine and front axles were purchased for around $800 from the salvage yard.

As fate would have it the Wagovan was not the perfect donor vehicle, at least not for this application. Being an older model the transmission utilized a cable clutch release and was designed for use with a cable driven speedometer, minor issues that could be resolved with a little ingenuity. The nail in the coffin was the fact that Honda had several different D-series transmission bolt patterns. This meant that the Wagovan's transmission, separated from an odler D-series engine, would not properly mate to the more current D16Z6 engine that was to be used.

One solution to this problem involves having a flywheel machined from scratch to properly clear a custom adapter plate to be used between the motor and transmission. While not a bad idea and commonly used when installing Subaru motors in older Volkswagon vehicles, it would make the engine and transmission assembly wider reaking havoc with mounts and clearances.

Another solution would involve removing the bellhousing half of the Wagovan transmission and replacing it with a brand new custom cast bellhousing that would mate to the newer D-series engines and use the newer hydraulic clutch release and Vehicle Speed Sensor. Far superior to an adaptor plate, this solution would work flawlessly and would appear as if the transmission had come that way from the factory. It is also incredibly expensive to commission just one unit with the custom molding, casting and machine work required to fabricate such a part.

Since the Wagovan's transmission would not directly bolt up to the engine that was slated for use, it was placed in storage and the other option, using parts from Honda's CR-V, was considered.

The CR-V was introduced to the US market in 1997 with the same series engine as most of their smaller passenger vehicles, the B-series, which used a hydraulic clutch release, a Vehicle Speed Sensor and had three common mounts. This meant that the engine and transmission from the CR-V would bolt into the engine bay of a Civic, Integra or CRX del Sol with very minor modification or fabrication. Only two issues with this configuration is that parts are scarce and expensive. The B20B engine from the CR-V can be had for around $800, the same ammount spent for two thirds of the Wagovan's drivetrain. For this reason the project was put on hold until June of 2005.

June of 2005 saw the del Sol's second rallycross event and new flame lit for the all wheel drive project. The very next weekend, which happened to be the Fourth of July weekend, fabrication began with the rear trailing arms.

The Wagovan's trailing arms were too long so they were sectioned and welded to halved stock trailing arms so that they would be the proper length. Now that the trailing arms fit the del Sol, it was time to modify the suspention to fit with the new trailing arms.

Since the Wagovan's trailing arm carried an axle hub, the lower control arm was located off center tward the rear for clearance. The Sol's lower control arm is located on center with the rear wheel bearing assembly. This meant that the entire rear crossmember had to be relocated a bit more than an inch tward the rear of the car. To do this the gas tank needed to be supported while the tank straps were removed, then the spot welds needed to be drilled out or cut. Once that is done the crossmember can be mocked in its new location and welded once proper placement is determined. Now the tank straps need to be lengthened to reach the crossmember in its new location. Shims were required to fill the gap at the top of the rear strut due to the recent modifications. After 10 days the car was back on the ground and roadworthy.

Since the Wagovan's trailing arm carried an axle hub, the lower control arm was located off center tward the rear for clearance. The Sol's lower control arm is located on center with the rear wheel bearing assembly. This meant that the entire rear crossmember had to be relocated a bit more than an inch tward the rear of the car. To do this the gas tank needed to be supported while the tank straps were removed, then the spot welds needed to be drilled out or cut. Once that is done the crossmember can be mocked in its new location and welded once proper placement is determined. Now the tank straps need to be lengthened to reach the crossmember in its new location. Shims were required to fill the gap at the top of the rear strut due to the recent modifications. After 10 days the car was back on the ground and roadworthy.

Since the stock location for the gas tank was right where the driveshaft and differential were to be, it was relocated to the trunk. Since the car is being built up for competition it will need to meet certain requirments and because the stock tank could not be used, a FIA approved fuel cell was needed. A FIA FT-3 spec. fuel cell was purchased through Pegasus Auto Racing online for around $950. A new seventy gallon per hour fuel pump was installed and was plumbed with stainless braided lines and AN fittings to the existing hard lines that ran the length of the undercarrage. This was completed tward the end of September 2005.

Since the stock location for the gas tank was right where the driveshaft and differential were to be, it was relocated to the trunk. Since the car is being built up for competition it will need to meet certain requirments and because the stock tank could not be used, a FIA approved fuel cell was needed. A FIA FT-3 spec. fuel cell was purchased through Pegasus Auto Racing online for around $950. A new seventy gallon per hour fuel pump was installed and was plumbed with stainless braided lines and AN fittings to the existing hard lines that ran the length of the undercarrage. This was completed tward the end of September 2005.

In November of 2005 a CR-V transmission and transfer assembly were sourced from HAP Recycling in Rancho Cordova for around $1000. An ACT Xtreme four puck unsprung clutch disc and Xtreme pressure plate were purchased from an ebay auction for about $300. A stock flywheel was provided by a friend.

Mid December of 2005 it was decided that the car should visit the California State SMOG Referee for inspection and to recieve an authorised engine swap tag. The fuel cell was disconnected and the stock tank reinstalled before the visit. The original engine in the car was a D15B7 and it had been swapped out for a D16Z6 in August of 2004. Unfortunately at the inspection it was brought to light that changing between these motors was considered a direct replacement and not an engine change, so no tag was issued. The car was brought home, stock tank removed and the fuel cell was reconnected.

The engine, a B20b, also from a CR-V, arrived late in december and was stripped down to the head and block. The timing belt and water pump were changed, as well as the intake manifold and valve cover for clearance and aesthetic purposes. The flywheel, clutch and pressure plate were installed and the engine and transmission were mated mid January of 2006.

In early Febuary of 2006 the D16Z6 engine and transmission were removed from the Sol and the B20B engine and CR-V transmission were installed. Two of the five engine mounts were fabricated and the cable shift mechanism had to be modified and bolted into place. Once that was done the cables were run and anchored.

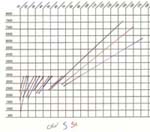

Before the transmission was installed in the vehicle, it was known that it would feel shorter due to the change in tire size. Numbers were crunched and it was found that it was about a gear short when compaired to the original transmission. With the CR-V transmission the car would cruise 70 miles per hour in fifth gear at about 3500 revolutions per minute. Using the stock transmission the car would cruise 70 miles per hour in either fourth gear at around 3500 revolutions per minute or fifth gear at about 2900 revolutions per minute.

Before the transmission was installed in the vehicle, it was known that it would feel shorter due to the change in tire size. Numbers were crunched and it was found that it was about a gear short when compaired to the original transmission. With the CR-V transmission the car would cruise 70 miles per hour in fifth gear at about 3500 revolutions per minute. Using the stock transmission the car would cruise 70 miles per hour in either fourth gear at around 3500 revolutions per minute or fifth gear at about 2900 revolutions per minute.

Since the CR-V transmission was purchased it was also known that the gear ratios between the Wagovan and the CR-V were different, though not by much. They were off by 1:0.004. That may not seem like much, but after a mile it was caluclated that the front wheels would travel 5280 feet while the rear wheels would travel 5300 feet, twenty feet farther than the fronts after just one mile. That would cause some serious tire wear if the Wagovan's rear differential was used with the CR-V's transmission. It was then decided that the Wagovan's differential could not be used and a CR-V differential was sourced for $850.

Gas milage has held steady at a respectable 27 miles per gallon with the new setup, however it is far from the 32 and 40 miles per gallon had with the previous engines.

The rear decklid was modified to carry a full size spare tire in a six inch recess. This was stared in April of 2006 and has not yet been finished because it will need to be modified further when the roll cage is installed.

May of 2006 marked the beginning of the end to the rear axle problem. The Wagovan's track width is smaller than that of the CRX del Sol which is smaller than that of the CR-V. Also, the two drivelines are built to different standards. The Wagovan was built such that it could be driven with just the rear wheels without strain. The CR-V on the other hand was built such that the system acted more like a rear wheel assist to the front, inteded to carry no more than half the weight of the vehicle. Since the Wagovan's parts are as robust as they are, they will not fit the smaller, lighter duty CR-V rear differential. Options were weighed and designs were drawn up, but the parts had been purchased and could not be returned. In late June of 2006 it was decided to modify the axles that were available and use them until they failed.

The Wagovan's track width is smaller than that of the CRX del Sol which is smaller than that of the CR-V. Also, the two drivelines are built to different standards. The Wagovan was built such that it could be driven with just the rear wheels without strain. The CR-V on the other hand was built such that the system acted more like a rear wheel assist to the front, inteded to carry no more than half the weight of the vehicle. Since the Wagovan's parts are as robust as they are, they will not fit the smaller, lighter duty CR-V rear differential. Options were weighed and designs were drawn up, but the parts had been purchased and could not be returned. In late June of 2006 it was decided to modify the axles that were available and use them until they failed.

Week of the Fourth of July 2006, one year after fabrication began, the upper mount for the CR-V differential was welded into place and the differential was mocked up. The Wagovan axles were instaled, measured for proper length, removed and cut. The CR-V axles were disassembled and the inner CV cup and bearings were installed on to the cut end of the Wagovan axles. The now hybrid axles were reinstalled and everything test fitted perfectly. The differential was mounted proper and the measurement for the drive shaft length was taken before disassembling the rear end so the vehicle would be driveable.

Week of the Fourth of July 2006, one year after fabrication began, the upper mount for the CR-V differential was welded into place and the differential was mocked up. The Wagovan axles were instaled, measured for proper length, removed and cut. The CR-V axles were disassembled and the inner CV cup and bearings were installed on to the cut end of the Wagovan axles. The now hybrid axles were reinstalled and everything test fitted perfectly. The differential was mounted proper and the measurement for the drive shaft length was taken before disassembling the rear end so the vehicle would be driveable.

Three weeks later the exhaust had been re-routed to exit the driver's side of the car and the drive shaft had come back from the shop and everyting was installed for the final time July 30 of 2006. The car was driven the following day without issue.

Copyright 2009